Buying Flame Retardant Fabric: What to Look for in Quality and Safety

2025-04-25 15:53

When it comes to ensuring safety in various environments, choosing the right flame-retardant fabric is paramount. Whether you are sourcing materials for industrial workwear, children’s clothing, or home décor, understanding the key factors that contribute to the quality and safety of fire resistant fabric is crucial. This article will guide you through important aspects to consider while purchasing flame retardant materials, helping you make informed decisions that prioritize protection and compliance with safety standards.

Understanding Flame Retardant Fabric

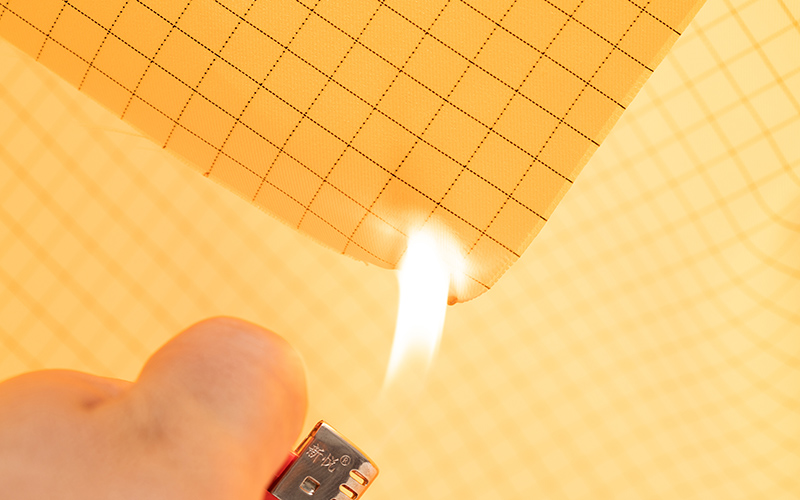

Flame-retardant fabric is specially treated to resist ignition and slow down the spread of fire. Various industries such as construction, oil and gas, and hospitality utilize this type of fabric extensively due to the inherent safety benefits it offers. However, not all flame retardant materials are created equal. To ensure that you are selecting high-quality options, it is essential to familiarize yourself with the certifications and standards that indicate reliability.

Key Certifications for Flame Retardant Fabric

One of the first things to consider when buying fire resistant fabric is the available certifications. Fabrics that meet safety standards set by organizations such as the National Fire Protection Association (NFPA) or the American Society for Testing and Materials (ASTM) are often your best choice. These certifications confirm that the fabric has undergone rigorous testing to assess its fire resistance capabilities, ensuring that it can withstand exposure to flames and heat effectively.

In addition to safety certifications, look for compliance with other standards that may apply to your specific industry. For instance, the OSHA (Occupational Safety and Health Administration) may have additional requirements for flame retardant fabrics used in workplaces.

Types of Flame Retardant Fabric

When browsing options, you will encounter a variety of flame-retardant fabrics. The choice between natural fibers, such as cotton, and synthetic materials, like polyester or aramid, can significantly impact performance and cost. Natural fibers are typically more breathable and comfortable but may require additional treatments to meet fire safety specifications. Synthetic options often provide superior fire resistance but might be less comfortable in certain applications.

Understanding the specific use cases for these fabrics will help you select the most appropriate material. For instance, if you are sourcing fire-resistant fabric for industrial use, you might prioritize durability and resistance to abrasion, while for children’s clothing, softness and comfort would be more critical.

Assessing Fabric Quality

Quality is another critical aspect of selecting flame-retardant fabric. High-quality fabrics are typically more durable, maintain their fire resistance over time, and provide better overall performance. Here are some factors to assess fabric quality:

Weight and Thickness: Heavier fabrics often provide better protection than lighter options. Assess the weight of the fabric to ensure it meets your safety requirements.

Weave Construction: The weave pattern can also affect fire resistance. For example, tighter weaves generally offer better protection compared to loose weaves.

Treatment Method: Various methods can treat fabrics, including chemical finishes or inherent fire resistance. Understanding the treatment process can inform you about the longevity and effectiveness of the fabric.

Finding Reliable Suppliers

CJTI is a professional flame retardant fabric manufacturer, specializing in high-quality permanent flame retardant fabrics, including aramid. Our products meet strict safety standards, ensuring maximum protection and durability in extreme environments. Whether you're looking for workwear solutions or customized functional fabric services, we are equipped to meet all your requirements.